Profile This cut will cut out a complete closed shape, but the side of the cut needs to be determined, e.g. For this sign we want the letters inset, so we will cut the inside of the shape.

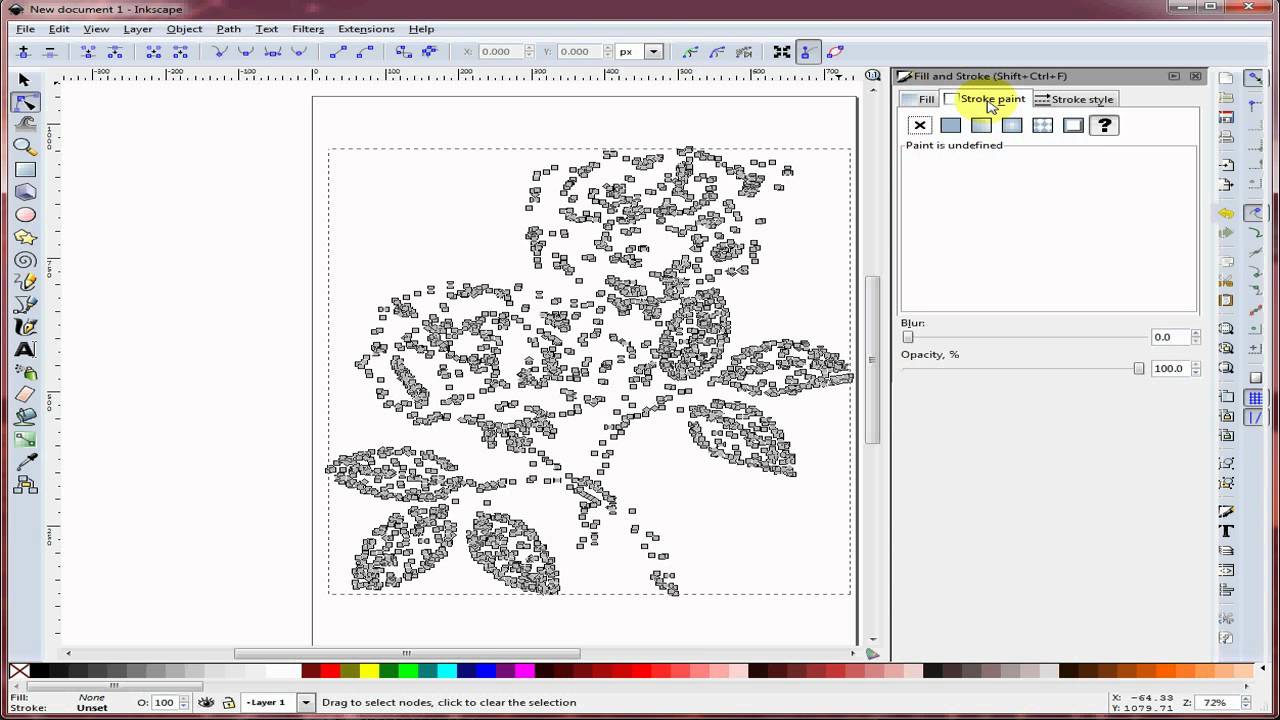

Set the text cut, which will only go partially through. The workflow is to load the file, define what kind of cuts are needed to produce your desired result, calculate the paths, add tabs, and export gcode. Using shift and control to group works fine, just use selection dragging instead of just clicking. More instructions to come using other software but this is a good tutorial and MakerCAM can be to the CNC what Inkscape is to the Laser.Ī note about selecting lines, it's best to drag the select square than try to click. However, if a mistake is made, it's possible to redo the operation, and at the end of the process, only export the operations you want. It's a web-based application and it's not great. Once complete, save the drawing as a plain svg. Paths are required for vector based plotter operations. This will break each object up and create a set of paths. Select All and then go to Paths -> Object to Path. Add a line underneathe with the line tool and surround it with a rectangle with the rectangle tool. If you are using 3/4" wood and you want to be absolutely sure the cut goes through, then you need to specify the cut depth as > 3/4". The z-axis for the maslow is the depth which the router bit descends into the material. For the Maslow, movement consists of left, right, up, and down. The way the machine knows to what to do and where to do it is location based commands which tell it where to move and how fast. Sometimes you want that tool to "work" aka be cutting, and sometimes you don't, so the machine can move to the next cut.

You have a thing that moves which has a thing that cuts on it. In this tutorial we'll cut a Noisebridge sign designed in Inkscape.

0 kommentar(er)

0 kommentar(er)